THE BEST EBIKE BATTERY

Cheap Li-ION ebike batteries

Which batteries are best for ebikes?

For the past 20 years, the best ebike batteries have used Li-ion 18650 cells. Li-ion has dominated as the best technology and advancing chemistry continues to increase capacity and reliability. Li-ion provides the highest power for size. It is reliable, light and cost effective.

For the next few years, the electric vehicle world will continue to use Li-ion chemistry and Li-ion continues to be the best option for most electric bicycles.

If you want maximum power for your dollar then lead acid batteries are the best option. The issue with lead acid batteries is that they are over 4 times the weight of Li-ion equivalents. For electric bikes, the extra weight of lead acid batteries is a problem for most riders.

Many alternative battery chemistries have shown promise over the years. Lithium polymer (LiPo), Nickel metal hydride (NiMH), and Lithium Ferrous (LiFe) have all tried and failed to better Li-ion.

There is, however, massive investment in a range of new technologies which extend the range that electric vehicles can travel before requiring a recharge. The most promising technology that is beginning to emerge is rechargeable hydrogen cells. [click here to read our article on ebike batteries using hydrogen cell technology]

Rechargeable hydrogen cells are available now although they are in an early phase of production. In 2021, this very new form of powering electric bikes is beginning to roll out in Australia. Hydrogen cells for electric bikes would be expected to reach Europe and the US in 2022 if the technology proves to be successful.

As the roll out of cost effective hydrogen cells is new to the market, it is still too early to say whether they will begin a revolution in powering electric vehicles.

Ebike battery replacement

Once you have coughed up the substantial investment required to purchase your e bike, you typically have a year or two of good use before the battery supplied with the bike begins to fail. If you can afford a brand name ebike, you would typically expect the battery to last two to three years before the travel distance becomes annoyingly short.

It is a shock to most e-bike owners that replacement batteries for most ebikes can be more than half the price of a replacement bike with the latest battery fitted. In addition, the rapid re-design of ebikes often means that it is difficult to obtain a replacement battery that fits your model bike.

When the battery dies, ebike owners are forced to seek a low cost replacement, or scrap the bike completely. The problem is that a good replacement battery by itself can cost as much as the e-bike with the battery included.

Why are cheap ebike batteries unreliable?

a) Battery Management Systems (BMS)

BMSs protect Li-ion battery packs from a range of potentially damaging issues. Batteries can be damaged if they are overcharged, drained excessively, discharged too quickly or if they overheat. BMSs ensure that the individual cells within the battery pack operate within their specified limits.

There are 2 types of BMS. The most important BMS is an overall management unit which manages all the individual cells within the battery pack. Each battery cell within the larger battery pack can also have individual protection circuits.

Battery cells with individual battery protection circuits can help to further protect each cell. They provide secondary protection if the main BMS is not providing sufficient protection for the cell.

Low cost batteries seldom use secondary protection within the cell as they are usually more costly and have a slight drain on the power of the cell. Ultimately, secondary protection within the individual battery cells is not necessary as the main BMS should provide good protection.

Low cost ebike battery packs use triple layer Printed Circuit Boards (PCBs) which are more prone to failure and cannot be cost-effectively repaired. Production line experts advise that triple layer PCBs have between 30-40% failure rate on leaving the assembly line due to warping effects.

Three layer PCBs offer a small cost saving over 4 layer technology but when price is of prime importance, reliability suffers.

China is the world’s largest manufacturer of cheap ebike batteries. Multiple layer PCB’s (4 layer or 2 layer) are more reliable but are difficult to source and are not produced in the same quantities in Chinese factories.

The greater complexity of 4 layer PCBs make them more expensive to design and produce. In addition, although 2 layer PCBs are usually cheaper, the circuit boards are larger and heavier than PCBs with more layers. As 2 layer BMS are not as popular in Chinese manufacture they are not in the same volume and, therefore, are more expensive.

In addition, the technology of poor quality PCBs can have an effect on the reliability of battery packs. Higher price PCBs can provide smarter cell maintenance to reduce the power supplied by the battery to better protect the individual cells in the battery pack from damage. Similarly, more expensive BMSs can protect individual cells from overcharging and overheating.

Electric bike batteries explained

To properly understand the issues that we encounter with low cost Li-ION battery packs requires a quick explanation of the battery pack construction.

Almost all ebike battery packs are built by connecting a number of smaller Li-ion battery cells together to build a greater storage capacity with higher voltage.

Li-ION battery pack construction

An introduction to 18650 cells

Most electric bike battery packs use 18650 Li-ION battery cells. These small, cylindrical battery cells are slightly larger than the 1.5 volt AA batteries that have been used in household flashlights for decades. The 18650 battery, however, packs a lot more punch than the average AA.

Each 18650 cell is rated at 3.7 volts nominal range although storage capacity for different brand and model batteries can vary significantly.

18650 capacity tests

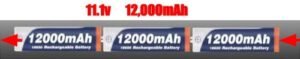

Some of the latest Chinese manufactured 18650 Li-ION battery cells claim storage capacities up to to 12000 mAh of charge. If these claims are true, this would represent a 5 fold increase in storage capacity over the past year. As the substantial increase in capacity seemed unusual we tested a range of battery cells to verify their capacity claims.

In our tests, high capacity Chinese battery cells such as ETSAIR, BXE displayed around 12% of their rated power. In contrast, brand name cells such as LG, Panasonic, Sony and Samsung all supplied between 92% and 100% of their rated capacity.

Our tests showed that brand name 2500mAh batteries lasted longer and supplied a greater charge than Chinese batteries rated with 5 times the capacity.

Be wary of Chinese manufactured Li-ion cells with high capacity ratings. These cells have now become mainstream in 2021 and can be purchased from Amazon and eBay in low volume for around US$4 per cell. These high rated batteries but do not perform as well as lower cost, lower rated brand name battery cells.

Building higher voltage and capacity packs

Connecting in series

To create a 36 volt battery, we connect 10 x 3.7 volt cells end to end.

Although the nominal voltage of 10 Li-ion cells in series should be 37 volts, marketing from lead acid technology of yesteryear persists. Sealed Lead Acid (SLA) batteries were manufactured in increments of 12 volts and 12v, 2v, 36v, 48v and 72v Li-ion equivalents can replace older SLA units.

The nominal voltage obtained by connecting 10 x Li-ion cells in parallel is 37 volts. Voltage is rounded to 36 volts to retain consistency and price/power/weight comparisons with similar voltage lead acid products.

Connecting in parallel

To increase capacity we can connect several cells together in parallel. 2 x 3600mAh batteries wired in parallel combine to provide a 7200mAh battery.

36v ebike battery

Using 3600mAh 18650 cells, a 36volt, 10Ah battery requires a total of 30 battery cells. (3 x 3600mAh cells connected in parallel with 10 of these units connected in series).

48v ebike battery

Similarly, if we use 3600mAh 18650 cells to fabricate a 48volt, 10Ah battery pack this would use a total of 39 cells. (3 x 3600mAh cells wired in parallel, 13 deep).

b) Missing cells

Over the past two decades of sales and repair of Lithium Ion electric bike battery packs, We have found that many low cost battery packs are supplied with insufficient cells.

This can only have two possible causes. Either bad quality control (or more likely non existent quality control) on the assembly line or deliberate cost reduction in the assembly plant. With low cost battery ebike batteries, we have found missing cells in around 1/5 of the packs we inspect.

The multitude of issues we have with low cost battery packs has forced us to dismantle every battery pack and double check a long list of items. We typically encounter issues with 1/2 of the batteries we inspect so are forced to undertake our own quality inspection and amend the faults.

This leads to power & recharging imbalance which rapidly leads to battery failure.

c) Variation in battery cells

We often find that battery cells vary within the battery pack. Some Li-ION cells are higher voltage or higher rated energy capacity.

Each 18650 cell is rated at 3.7 volts nominal range, however, storage capacity has improved over the years. Each cell can hold anywhere from 1800mAh to 3600mAh of charge.

In addition, a 3.7 volt cell is a nominally rated voltage. A 3.7 volt cell can vary in voltage anywhere between from 4.35 volts when fully charged (latest Li ION chemistry) to 3.0 volts when discharged.

In both of these cases the BMS cannot properly regulate charging current. Some cells are over-driven while others are under charged. Battery cells are sensitive to overcharging, over-draining and overheating. A mixture of battery cells leads to rapid deterioration of battery performance and early failure.

Incorrect wiring

We have had several batteries that were wired in reverse where the black ‘earth’ wire was positive and the red wire was negative.

We had a batch of 100 batteries from a Chinese manufacturer which had the battery connection plug connected at random. 50% of the batteries were wired with the positive and negative terminals reversed.

In addition, the connector leads were also connected at random so 50% of the connecting leads were also reversed.

On top of this, we have had the same issue with battery charger connectors wired in reverse.

Replacement

What is the solution, how can we find a reliable, well priced battery?

1. Build your own battery pack

The first option is to build your own ebike battery pack. The issue here is that not everyone has the expertise, or equipment, required to undertake the task. In addition, purchasing all the individual components is expensive. Further, many of the individual components (especially the BMS) can still be poor quality.

There are advantages of building your own battery packs. Manufacturers use rigid metal frames to hold the individual battery cells. Rigid battery frames do not absorb impact or vibration well and tight packing provides poor heat dissipation. Heat and vibration are both bad for battery longevity. Patience and thought in placing the battery cells and BMS can provide the opportunity to use looser packing with rubber cushioning. A little thought in the placement of battery cells and BMS can make a big difference to the life expectancy of the pack.

Misrepresented cell capacity

In 2020 and 2021, the retail market has been flooded with 18650 Li-ion cells that advertise huge leaps in electrical storage. If capacity claims are to be believed, the capacity of 18650 cells have increased three fold in the past year. These Chinese manufactured cells are available on Amazon and eBay at the same price as lower capacity 18650 cells.

As the latest 18650 cells claiming to provide 120000mAh have only been readily accessible for the past few months, we have not yet had sufficient time to ascertain whether these high capacity units will prove to be reliable, however, we have tested the high rated cells with surprising results.

Brand name battery manufacturers such as Sony, Samsung, LG and Panasonic have yet to market 18650 cells with capacity beyond 38000mAh. Our tests appear to provide the reason why brand name companies are not producing batteries with these much higher charge capacity.

Our tests compared several brand name 2500mAh battery capacity against Chinese brands claiming 98,000mAh, up to 120,000mAh. In our tests, brand name 18650 cells of 25,000mAh out performed Chinese brand batteries claiming to have over 4 times the capacity.

Where brand name producers supplied between 92% to 100% of their rated capacity on our tests, Chinese 18650 cells could only manage 12% to 13% of their rated capacity.

In short, you get more “bang for your buck” with lower rated brand name cells than with Chinese cells claiming substantially more capacity. (bang for buck is, perhaps, not the best cliche to use with reference to Li-ion batteries).

2. Find a custom manufacturer

Custom built batteries can be expensive but are usually far lower cost than brand name manufacturers batteries.

To reduce costs, try to find a factory that supplies batteries to Europe

Europe and the UK have strict quality control standards for batteries. If the manufacturer supplies batteries, on mass, to the European Community then it is a good bet that they are a huge leap above the quality of other manufacturers.

Similarly, if you know of local factories that have high quality control standards then safety regulations, quality control and assembly training in Western countries tend to be higher than generic Chinese manufacturers.

Kits

Many local factories also sell battery kits to allow you to build your own battery pack to your preferred standards. These kits provide the parts and guidance the average person needs in order to avoid the pitfalls of constructing your own electric bike battery.

These kits provide compatible battery components and all the basic building blocks at a lower price than a fully built battery pack.

Kits offer the advantage that you can adjust the shape of your pack and create padding ans space within the pack to help protect the cells.

Ebike battery charger

The choice of battery charger for your ebike is very important to the performance of your battery.

If you purchase a Li-ion electric bike battery you will usually receive a charger specific to the pack. The reason for this is that Li-ion cells are built to different standards and some can accept a slightly higher charge than others.

A higher range of voltage (from fully charged to fully discharged) will result in a higher capacity battery. As consumers like high capacity batteries, manufacturers seek to charge their products a little higher and discharge a little further.

The problem with this is that Li-ion batteries are very sensitive to over charge and excessive discharge. A charger delivering 0.1 volt above the capability of the cell can not only ruin the battery but creates fire and explosion hazards.

Good BMS systems and protection circuits within the Li-ion cell offer a level of protection to protect from overcharging but secondary protection is not as good as not creating the hazard in the first place.

In addition, if the charger supplies less than the batteries rated voltage, you are not obtaining the full charge that the battery is capable of providing.

Care for your investment

It is important to properly care for your ebike battery throughout it’s working life.

We have provided some simple tips that will extend the life expectancy of your battery and delay the inevitable replacement.

Extending the duration of your battery by one year could save you thousands of dollars over the life of your ebike.

Click here to read our article on ebike battery care.

Conclusion

Replacing ebike batteries are the single most expensive component of electric bicycles and they will need to be replaced after only a few years.

There are cost effective options to replace your failing pack but owners should be wary of purchasing cheap, no brand batteries from Amazon.

One of the best options for upgrading and replacing your ebike battery is to build your own. Replacing the 18650 cells in your pack can be the most cost effective option for many.

You do, however, need to be aware of misleading claims of misleading claims of charge capacity. Non brand name 18650 cells which claim to provide charge capacities above 3000mAh are usually misrepresenting the capability of their product.

Hi Steve, Thank you for a really good read on ebike batteries. Three couples (6 friends) all purchased ebikes about three years ago and are in need of replacements. They asked me if I’d try to rebuild for them. I am pretty handy, and already have the necessary tools but don’t know where to get good 18650 batteries at a decent price. I might start a side business doing this, so starting at 1,000 batteries isn’t too far out of my imagination. Any tips? Thank you in advance.

Hi, I would suggest you stick with 2500mAh brand-name batteries from Panasonic, Samsung, LG, and Sony. They all had comparable power output in our tests. They all have a reputation for reliability, but it is difficult to determine which lasts longest until you have undertaken a 2+ year field trial on each of them.

In our tests, these brand-name batteries performed better than “high powered” Chinese cells claiming to have almost 10 times the capacity. In the field, Chinese brand batteries last 1 – 2 years where LG has lasted around 3 years. I have not had a good experience with Samsung lasting around 2 years. Most of our battery packs over the years have been LG, Samsung, or Chinese brands.

As they don’t cost more than standard cells, it makes sense to look for batteries with inbuilt protection circuits in the cell (again, I have not tested these cells but theoretically I would expect them to be better).

The overriding suggestion I would make is to acquire a top-shelf brand name battery management system. The market is flooded with cheap Chinese options that require substantial time to test and evaluate. My gut feeling is that Western options will be twice the price, but will conserve the life of the battery pack far longer.

I would suggest Amazon as the best place to acquire well-priced battery cells until you require larger shipments.

I just like the valuable information you provide for your articles.

I’ll bookmark your weblog and take a look at once more right here regularly.

I’m fairly sure I’ll be told plenty of new stuff proper here!

Good luck for the following!