Electric Bike Conversion Kits

How to convert your bicycle to an eBike

Ebike conversion kits

Convert your bicycle into an electric bicycle

We step you through the process of installing an electric bicycle motor onto your bicycle. Homemade electric bicycles are a fantastic way to begin cruising the streets in style but can be daunting for some.

Many e-bike enthusiasts purchase a purpose built EV, but there are huge advantages to building your own using an electric bicycle motor kit.

E-bike motor kits remove the complications that can cause problems on purpose built EV’s.

If you have a loose wire on an e-bike, it can be a nightmare to find. Purpose built e-bikes hide the wires inside the bicycle frame, and the wire coding can change in a concealed junction. It can be a challenge to trace wires and understand what they are for. Ebike electrics are further complicated by the addition of ignition switches, lights, programming functions, special charging modes and a host of other feature.

Bicycle motor kits are simple by comparison. The wires and connectors are straight forward, easy to follow and open. Connectors are all specific, so you cannot confuse the connections.

Installing an electric motor kit can occasionally resent challenges. This guide de-mystifies the installation process and highlights points that you should consider before buying your bicycle motor kit.

ebike conversion kit

A step by step guide to converting your bicycle to an ebike.

Convert your bicycle to an ebike

We step through the installation process for converting your bicycle into an electric powered bike. We cover the installation of the most popular rear wheel ebike conversion kit and provide solutions for common issues.

All electric rear wheel, electric, hub motor kits follow this installation process.

Why choose a rear wheel ebike conversion kit?

Rear wheel ebike conversion kits are the most readily available kits for a reason. Hub motors are lower cost than central mounted electric motors that drive through the bicycle chain. They are, however, just as efficient as central mounted motors and can be easier to fit in many cases.

Although front wheel ebike conversion kits are usually a little cheaper and easier to fit, these are not recommended. Front wheel conversion kits have a number of issues:

1. The first is that they feel awkward to ride. The bike pulling from the front takes a little time to get used to.

2. As there is less weight over the front wheel, front wheel ebike motors lose traction easily on wet roads, dirt tracks and hills.

3. The weight of rider and bike is leveraged through the front forks. The bike and rider being pulled along by the front wheel causes strain on the steering head weld. We have had several reports of riders flying over their handlebars as the motorized wheel is ripped away from the steering head of the bike.

Electric Hub Motor Installation

It is recommended that this guide thoroughly before purchasing an ebike conversion kit. The guide will ensure that you select a suitable conversion kit for your style of bicycle.

Before commencing work, you should be familiar with the various components in your electric motor kit and where they will fit on your bike.

Thinking things through and planning how things may fit will make the job much easier down the track.

Most rear wheel, electric hub motors motor are 5 3/8 inches wide in order to fit standard bicycle frames.

Many motor also have a wide, stronger cross section, axle which has been shaped at the mounting points to fit standard size bicycle axle locators.

When fitted to a standard bicycle frame, the re-designed axle on the hub motor prevents “torque twist” from the power of the motor while providing additional strength to the rear hub.

Check that everything is OK and nothing has been damaged in transit.

If you ordered any extra items, make sure they are there and motor is the model you ordered. If anything is amiss, contact your supplier straight away.

Electric hub motor installation instructions

INSTALLING THE EBIKE CONVERSION KIT

Remove bicycle wheel

A 12mm spanner will loosen the axle nuts holding the rear bicycle wheel in place

Getting Started

1.1 Remove the Original Wheel

Release the brake cable tension to clear the tire. Release mudguard stays to aid wheel removal.

Loosen the flange nuts of both sides of the rear axle with a suitable spanner. Remove the small retaining screw and remove the Derailleur (if fitted).

Turn the bicycle over and use the handlebar and saddle to stand the bike up.

Remove the chain from the sprocket or cluster and remove the rear wheel.

Check the width of your rear Dropout

Check the width of the rear axleon your bicyle. This will determine the width of the electric hub motor you will be able to install.

1.2 Check the width of the Dropout

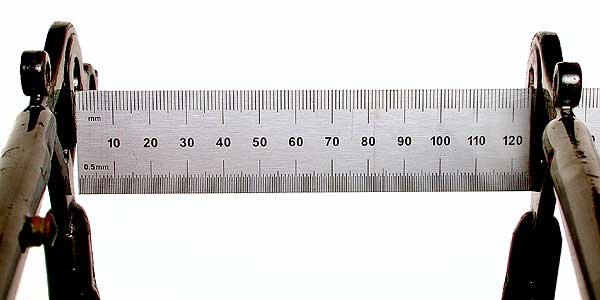

The standard dropout distance on most bicycles is 13.5cm. If your dropout is undersize by more than 5mm, the forks will need to be spread to allow the axle and wheel to fit. The RH fork will need to be made wider since the alignment of the wheel is based on the position of the LH fork.

The electric hub motor is designed to fit in this dropout if a single, or up to a three sprocket cluster is used. A greater number of sprockets will require an extended width of the dropout and the need of a spacer to be fitted to the axle.

1.3 Rear Sprocket

Rear Wheel Sprocket Mount

A rear sprocket is often fitted to assist installation. If required, this gear cluster can be replaced with a larger or smaller gear cluster to suit your preference. Bear in mind that you will not require a high selection of gears as the electric motor will be taking the brunt of the work. Before changing to a larger gear cluster you should verify that you have sufficient width in your frame to accommodate fitting. To remove your original gear cluster from your bicycle, you need to use a gear cluster socket suited to your model of bicycle and a socket and wrench to loosen the cluster. Ensure the cluster thread is not damaged if you intend to re-install it on the electric hub motor wheel. Professionals use an impact wrench to release the sprocket as excessive leverage can cause damage.

Removing the sprocket assembly can be a difficult task requiring special tools. It is recommended that you use a bicycle specialist to remove your gear cluster and install it on the new wheel. Bike shops will usually do this for free or for a small charge.

Replacing gear clusters

Gear clusters are normally fitted to rear wheel electric hub motors, however, you way wish to re-use the gear cluster that came with the bicycle wheel.

Disc brake Spacer & Washers

1.4 Remove the Brake Disc.

If your bike has a brake disc that screws onto the LH side of the hub you can use it on your electric wheel. There are locating holes to fit a disc brake mounting bracket.

Note that there are many types of disc brake mounts so not all can be accommodated. The locating points on the left side of the hub motor are designed for the most popular fittings.

1.5 Remove Tire and Tube

If the tyre and tube is a 26”x 1.5” to 2.25” you can use these items on the hub wheel. If the tire is worn it is best to replace it and buy a tire that has a ‘road’ tread. Off road treads won’t last long on a motorized bike. There are many good videos on U-tube that will show you how to change a tire.

Gear Cluster Spacer & Washers

Larger gear clusters will often require a spacer. This is needed to prevent the frame rubbing against the gear cluster.

1.6 Prepare the Ebike Hub Motor for Installation

Install the tire and tube and inflate to the maximum pressure recommended on the tire (or within 5 PSI). Low pressure is a common cause of a blowout! If you are using a disc brake, install the disc hub and disc in the reverse order of removal.

You will need to prepare a spacer to prevent the cluster jamming against the frame of your bicycle (see ‘metal Tube’ in the image below). A spacer can be made from a piece of water pipe or similar material 5/8th inch inside diameter and needs to be of a length that will allow it to protrude a minimum of 1/8 th inch beyond the outer edge of the cluster.

1.7 Mount the EBike Rear Wheel

Fit the wheel onto the forks with the power cable on the LH side (see image below) and with the notch in the axle facing forward. Use the spacer (if any) the washers ‘O’ (shown in image above) to position the wheel centrally in the frame. The ‘Q’ washer fits on the outside of the fork with the ‘tang’ facing inboard and located in the slot of the fork.

Screw on the gear cluster

Although removing the gear cluster can be challenging. it screws on by hand. No tools are needed and the cluster does not need to be tight. Pedaling will tighten the gear cluster naturally.

Tighten Axle Nuts on the hub motor

There will be more load transmitted through the axle of a motorized wheel so retaining nuts should be securely tightened.

If a derailleur is to be used, install it now (if it is not already in place). Position the axle of the Hub Motor Wheel assembly so it sits central in the frame (use the washers etc to aid the location.

Install the outer washers and nuts and secure the wheel assembly to the frame. Install the pedal chain and check operation.

Note: The wheel should rotate freely in the forward direction but there may be some resistance when rotated backwards. The retaining nuts need to be very tight (30 ft/lbs) to prevent movement during operation

INSTALLING THE BATTERY PACK RACK (Rear Mounted Battery Packs Only)

Mount the rack arms on the seat post clamp, then tighten the binder bolt.

If you installed the brake caliper bracket, place the washers and accessories according to the sequence, the sequence from inside to outside should be: Brake disc, Caliper bracket, Dropout, Q-washer, Rack leg and Flange nut. If you don’t install brake caliper bracket, you must insert the metal tube. The sequence from inside to outside should be: Brake disc, Metal tube, O-washer, Rear dropout, Q-washer, Rack leg, O-washer and Flange nut.

Fitting a parcel rack

Parcel racks are often required to mount batteries.

Install rack leg at freewheel side.

First, pull away the derailleur cable, then make the motor cable pass through the rack leg hole from inside to outside and place this leg on the rear axle. Notice that the motor cable should not twine with other cables

The sequence of washers and accessories at freewheel side from inside to outside should be: Freewheel, Metal tube, O-washer, Rear dropouts, Q-washer, Rack leg and Flange nut.

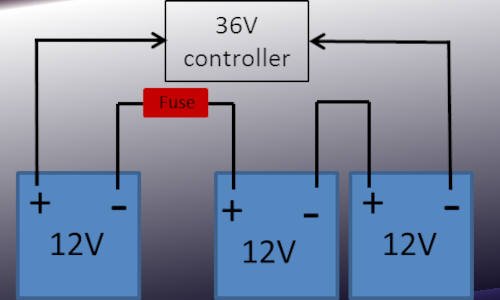

3.1 BATTERY CONNECTIONS (Lead Acid Batteries only)

A 250 Watt hub motor requires 36Vbatteries to run efficiently. These voltages can be achieved by wiring 3 x 12 Volt batteries in series. The diagrams below show how to wire the batteries, and position the fuse, for the motor.

Before connecting the battery pack to the controller double check that the polarity is correct – In other words, make sure that you are connecting the positive battery terminal to the positive wire of the controller (Positive connecters are indicated by red color or “+”).

Incorrect polarity could damage the controller.

Gas Bicycle Engine tuning

We all want to squeeze some more performance from our bicycle engines. See some quick, simple and cheap tuning options that will have your bicycle tearing up the road.

Battery care is essential to extend the life of your battery pack. The charger pack supplied with your motor has an intelligent sensor that reduces the charge supplied as the batteries reach their peak power. Even with the use of intelligent charger systems, batteries will be damaged by prolonged charging or allowing them to completely discharge.

Batteries will take around 8 hours to charge from full discharge to peak charge. Battery charging is indicated by a red light on the charger. You should take batteries off charge as soon as they have reached their peak capacity (indicated by the charger light turning green).

For greatest battery life:

Never discharge batteries to less than 20% of full power;

Always recharge the batteries as soon as possible after use. Don’t store in a discharged state;

Remove the batteries from charger as soon as peak charge is reached.

Never allow batteries to charge for extended periods.

Always use the intelligent charger supplied with your kit;

When storing for long periods, fully charge the pack and re-charge for a few minutes once a month.

- Consider solar options to power your e-bike

4. Remove and Fitting the Handlebar Components

4.1 Removing handlebar components

Bicycle Twist Grip

Slowly pull and twist the handle grip twist grip by hand to remove both grips. If available, use compressed air (blown between the grip and the bar) as you twist the grip to assist removal. Loosen the right hand brake lever and derailleur retaining bolt and remove the front brake lever.

4.3 Install the Electric Bike Brake Handle

Push on the brake handle and tighten the screws. As a safety mechanism, there is an electric cut-off switch in the brake lever. The brake lever will disconnect power to the motor when the brake is engaged. The brake lever supplied can be fitted to either side of the handlebars, however, we advise that the cut-off brake lever be fitted to the RHS as operation of front brake and power together has the potential to create a hazard.

The brake signal cables pass through the space between handlebar, the cable of derailleur controller, and brake cable, to allow easy wiring later.

4.2 Preparing the Handlebars

Push your derailleur controller further in towards the center of the handlebars to make room for the twist grip throttle for your electric motor and ‘power cut’ safety brake lever. Leave approximately 6 inches for electric bike brake handle and throttle and tighten the derailleur controller in place. Some bicycles use twist grip style derailleurs which can jam against the bend of the handlebar. If this occurs, you can replace the twist grip control with a thumb shift controller. These can be obtained from most bicycle stores.

4.4 Install the Throttle

A twist grip throttle is supplied with your electric kit. Push the throttle twist grip in to the right side of the handlebar. Move the throttle so that you can see the power indicator when riding the bicycle and tighten the screws.

5. Install the PAS (Pedal Assistance System)

5.1(a) Remove the Crank Arm

Take off the cover of crank arm with flat-tipped screwdriver. There are a variety of crank arm connectors. Most crank arms can be removed with a hexagonal socket. Unscrew the fixing nut with the appropriate tool.

5.1(b) Remove the crank arm (Crank Arm Remover)

Screw the crank arm remover in place and then screw the bolt of the remover with spanner. Note that the screw thread of the RH pedal is normal, however, LH pedal is a reverse screw thread. The pedal sensor should be fitted to the RH pedal.

5.2 The PAS Installation

Loosen the bottom bracket cap with the hook spanner (Using flat-tipped screwdriver and hammer instead if you haven’t a hook spanner)

Place the magnet plate to spindle, make the arrows’side face to you, the arrows indicate anticlockwise. Leave a gap of 3mm between magnet plate and sensor.

5.3 Install the Crank Arm

Install the crank arm on the spindle. Hit it tightly with rubber hammer. Then screw the nut with hexagonal socket, and push on the crank arm cover.

Hub motor controller

There are a number of positions where the controller can be mounted:

6.1 Mounting the Controller

Solution 1 : Place the controller in the side pocket that has been designed to hold the controller.

Solution 2:Mount the controller under the quick release rack with zip ties, the harness is towards the saddle.

Solution 3:Mount the controller on the top tube with zip ties, the harness is towards the rack, leave 5cm space between controller and seat post. Please avoid the derailleur and brake cables when you fix the controller.

7. Connect the Controller Cables

All connectors are specific to the components and match up with the corresponding connector in the controller. All components must be connected to the controller – Battery, hub motor, throttle. The safety brake and PAS are not essential to the operation of the electric motor but should also be connected.

8. Wiring

Wrap each exposed thread with black insulation tape.

Manage the cables near the handlebars

Don’t bind the signal cables of brake handle and throttle together too tight in order to let you can control the handlebar with full range

Fix the cables on the frame:

Fasten the cables on the top or down tube according to your bicycle’s type. If your bicycle is with a rear suspension, you’d better choose top tube where to fasten the cables. Otherwise, the cables may be pulled off when the suspension works.

If you have to fix the cables on the down tube for a bike with rear suspension (we don’t recommend you to do this), fasten the cable with buffer for the suspension working.

Wind and fasten the excessive cables under the rear rack and near the seat post

Avoid the brake and derailleur cables when you wiring on the down tube.

When you wiring on the bike with rear suspension and rack, it is better to fix the brake and throttle cables on the top tube.

You should leave some cable play when wiring the motor cables, otherwise, the cables may be pulled off when the suspension moves.Fasten the motor power cord and HALL signal cables

Fix the motor cable on the leg of rack with zip ties. Fasten the excessive motor cable on the rack’s leg for easily cooling.Wind and fasten the cables connect battery and controller near the rack and seat post with zip ties.