The best spark plug for bicycle engines

The best spark plug for standard bicycle motors is the NGK BR6HS with the gap set to 0.03″. If you have a highly tuned motor then the NGK BR5HS or BOSCH WR 7AC are the better choice.

We chose this brand of spark plugs for a few reasons:

1. NGK spark plugs are the most prolific. You can find them in any garage or parts store.

2. NGK have race backed reputation for reliability and performance.

3. They have a huge variety of alternative options that are useful in different scenarios.

4. Their spark plug codes provide clear data on heat, thread length and electrode protrusion.

NGK spark plugs codes

The letters and numbers on NGK spark plugs allow the engine tuner to vary the plug to suit the conditions of the engine. To decipher the most common plug we use, the BR6HS:

B = Thread diameter. (14mm thread is required for bicycle engines)

R = Resistive. The resistance of a plug can balance the resistance from the cdi and HT lead. If the resistance of plug and HT/cdi are balanced it provides a stronger spark.

6 = Heat of the spark. The higher this number the COOLER the spark on Champion. We find 2 strokes run best with spark plug heats between 5 and 8. Hotter plugs improve combustion, make starting easier and reduce coking in the cylinder head and piston. Hot plugs may cause the engine to run overheat. A warning for other spark plug brands here: Most other spark plug brands get hotter as the number increases.

H = Thread length. (1/2″ long thread for H plugs.)

S = Electrode construction (S stands for standard in our case)

For a full range of spark plug codes go to https://www.sparkplugs.co.uk/spark-plug-symbol-codes/

Resistive spark plugs

Resistive spark plugs are marked with an “R” on NGK brands. The added resistance of a plug can often help to provide a stronger spark.

We have found that resistive plugs work well in bicycle engines.

Electric theory tells us that a variation in resistance along a path attenuates in two ways. Their is a power drop across the resistor which is bad but there is also a less understood benefit.

Electric wave pulses can be reflected by changes in resistance. There is a natural resistance of the cdi and the HT lead connection to the spark plug. The strongest spark is obtained when all components are balanced. Resistive plugs help balance the resistance of the path.

OEM spark plugs

We prefer NGK spark plugs because they provide consistency. We know what to do if a plug is too hot or cold, if we want to try a longer electrode or push the spark further toward the center of the combustion chamber.

This is not to say that the standard manufacturers Z4C or Z8C are bad. We have never found fault with these manufactures plugs.

Our main concern with OEM plugs is the lack of data about them. For example, we have found no difference between the Z4C and the Z8C. They look identical and behave identically. One does not seem any hotter or display any differentiating properties to the other. We have repeatedly requested information from our Chinese suppliers but they are unable to provide any useful data. We simply have to test the options they provide to verify how they perform.

There are other Chinese spark plugs available for bicycle engines. Some have longer thread length with projected electrodes and even tri-electrode plugs. We test these as “one off’s”. We put the plug into an engine and evaluate how the plug performs. If we feel the plug needs to be hotter, the thread longer or the electrode reach further into the combustion chamber, we are lost. There are no alternatives other than go back to Champion or Bosche brands.

Tri-electrode spark plugs

We have used a multitude of spark plugs over the years with no clear all round winner. In most engines we have tried, the standard Chinese Z4C or Z8C plugs work as well as any Bosche or Champion equivalent. In many cases, this includes highly tuned bicycle motors.

For some engine brands we found that the tri-electrode spark plugs improved torque slightly although some engines ran poorer. It was the same with long reach, long nose Chinese plugs. There was no consistency that we could establish. Some engines run well with tri-electrode spark plugs and others ran better with long nose or standard plugs.

Spark plug gap

The plug gap is difficult to vary on tri-electrode plugs so we did not attempt this. We have, however, tested spark gaps for standard electrode plugs.

We found that the best spark plug gap was 0.03″ (or 0.75mm). Smaller gaps provide a shorter spark which makes starting more difficult and reduces torque.

Wider gaps begin to weaken the strength of the spark with a similar effect. The maximum gap with a standard ignition/cdi was around 0.04″ (1mm) before the spark could not jump the gap effectively.

We expect that some performance improvements with the tri-electrode plugs may have been because they are naturally better keyed than regular spark plugs.

Electrode position of Spark Plug

Keying the spark plug is not often thought about. It is simply adjusting the position of the spark plug to orientate the electrode in a preferred direction. We have found this simple technique quite helpful in increasing low end torque and we use this technique in all our tuned engines.

The spark plug is best positioned with the open end of the electrode facing the carburetor. The problem is that every bicycle motor cylinder head has a slightly different spark plug thread machined into it. To key the plug you have to remove the cylinder head and torque the spark plug down to visually verify their orientation. We have hundreds of spark plugs at our disposal so it is relatively simple for us to grade plugs with a key position. If you do not have access to a range of plugs then a variety of thin washers will help you key the plug correctly.

What is Spark Plug Indexing ?

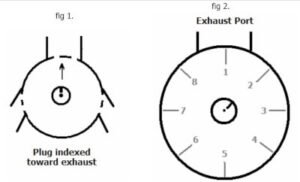

There is a term in engine tuning circles referred to as “Spark Plug Indexing”. Indexing is the process of making sure that the earth electrode on the spark plug faces in a particular direction when the plug is tightened to the correct torque (see images below).

Plug indexing in 2 stroke and 4 stroke engines

Fig 1. shows a spark plug indexed toward the exhaust port on a typical two stroke

motor and fig 2. shows the indexing numbering system I use to standardize the

index of the spark plugs I use.

Why index the spark plug ?

Some motors are found to run better, in some way, when the spark plug faces particular direction.

Some motors like the plug to face the exhaust, others the opposite, and yet others simply don’t care. There is some debate as to the value of Spark Indexing and I can understand where this comes from. Experience is the only measure for this sort of configuration change and I have had lots of it.

I have found that a given model of motor with one particular carbie setup or a specific exhaust pipe, or even a particular fuel, will not benefit from plug indexing. However, when only a small change is made (such as a main jet size change), suddenly, with a plug indexed either to face the exhaust port or perhaps the reverse, the motor shows a marked performance improvement at some point in the speed range.

The one thing I know is that with bicycle motors, there are absolutely no rules with this phenomenon. Having said that, in order to have a consistent evaluation of motor performance, I always index the spark plug toward the exhaust initially.

If the motor seems unhappy, I may try a plug pointing in the opposite direction. Although I have said there are no rules, I have found a trend that some motors benefit from an increase in top-end power with the plug indexed toward the exhaust, while others develop more torque when the plug is indexed 180˚ from the exhaust.

How to index a spark plug

If you have only one or two plugs for your motor the simplest way to index a plug is to use indexing washers. The best sources for these washers are Amazon or eBay. You can also try automotive spare parts stores such as Supercheap Autor, Autobarn, Repco etc. Always email the supplier to get the correct freight cost to your location; it will often be a fraction of the advertised price.

Once you have a packet of washers, follow the process below

- With a Sharpie pen, or similar, mark the plug in line with the gap.

2. Screw the plug into the cylinder head and torque to the specified tension.

3. Note where the mark is positioned and if it is not aligned where you want, continue with step four.

4. Remove the plug and fit one of the indexing washers.

5. Insert the plug and torque it down again. note where the mark is aligned.

If the alignment is not correct, repeat the process until you get the plug in the correct position.

Using pre-indexed spark plugs

If you have many (40-100) plugs that suit your motor, you can sort them by index number (referring to fig 2) and select the plug that suits your motor. This is the method I use so I can supply the correctly indexed plug to my customers in the rare event they need a replacement plug.

First you need a ‘Standard Master’ as a reference. It does not matter what it is as long as it has the appropriate thread and seat for the washer face (I use an old cracked cylinder head). On the side where the electrode is visible, mark the ‘Master’ as in fig. 2. I have containers numbered one to eight for storing the plugs. This makes it easy to simply grab a plug that is already indexed to the position I need. Screw the plug into the ‘Master’ and torque to the correct tension.

Note the alignment position and either write the number on the plug or place in the appropriate container.

Continue the process until you have a number of plugs for each number. Now you have a batch of indexed plugs, you will find it relatively easy to set up a plug to the correct position in the motor.

Take a plug indexed to ‘1’ and mark where the gap of the plug is, then install it in the motor. Note where the mark aligns relative to where you want the gap to be. If the mark is in the number ‘4’ position compared to where you want it, if you fit a number ‘4’ plug, it should then be aligned at the required position. That’s it, you’re done!

I’m trying to find a spark plug ending in …….LD.

I HAVE no idea where to find one

I bought a 100cc bike motor and everything is hooked up correct and I’m not getting a spark . won’t start do you have any suggestions?? Please reply need help . Thanks

Hey Therе. I found your blog using msn. This is a

very well written article. I will mɑke ѕure

too bookmark it and return to read more of your ussful infⲟ.Thanks for the post.

I will certainly comeback.

What is the best gap for 100cc bicycle engine?

Hi Travis, Occasionally, motorcycle manufacturers will recommend slightly different settings to the spark plug manufacturer, however, 99% of the time the engine and spark plug manufacturers are in sync. Manufacturers occasionally suggest a different gap, however most spark plugs work best with 0.25mm gap.

I bought a 100cc bike motor and everything is hooked up correct and I’m not getting a spark . won’t start do you have any suggestions?? Please reply need help . Thanks

Hi Earl,

There is a logical approach to engine faults which I have detailed in this article: http://power-bicycle.com/tuning/motorized-bicycle-starting/

I am sure that this article will be useful as it addresses your problem step by step. The most likely problem is your CDI or magneto (assuming you have a 2-stroke engine). Most modern 4-strokes have an electronic ignition system.

There are a few simple tests to go through in the link that will help you isolate the culpret.

OK. Thank you! I think I’ll try the NGK BR6HS

i like to see this on a dino …

Hi Jeff, I have had many years testing a variety of plugs and had thousands of customers provide feedback. Unfortunately, all tests involve trial and error and personal feel for how the bike runs. I never had the time or money to test the products on a dyno.

Pulstar are Supposed to be good but i cant find the Size for this motor ( 80cc/66)

I’m not that much of a online reader to be honest but your sites really nice, keep it up! I’ll go ahead and bookmark your site to come back later on. All the best