Bicycle Motor NT Carburetor Tuning

Changing the main jet size on the NT carburetor is the usual means of changing the ‘tune’ of a motor. Often, the following items are overlooked.

The NT carburetors series are about as simple as they come. The design has been used on small engines since the early 1940s, and probably even earlier. Despite its simplicity, when set up correctly, the NT carburetor is still hard to beat for performance and reliability.

NT Carburetor Tune Up Kits

NT carburetor Tune Up Kits are offered by many bicycle motor vendors. The kits provide a variety of fuel jets to assist with optimizing the carburetor performance.

Tune up kits are not essential, but provide useful assistance. Kits provide a range of fuel jet sizes that can be used to vary the fuel : air mixture. In most cases, the standard 0.65 mm jet (on 80cc bicycle motors) is usually the best option.

These notes will help you get the best performance from your NT carburetor, however if the motor is not in good running order, no amount of ‘tuning’ will make much of a difference.

Checking that the motor runs properly before attempting to tune your NT carburetor will save time and heaps of frustration.

Check the following and correct any faults:

- Does the motor run normally and produce reasonable power?

- Are there any signs of combustion gas, oil or fuel leaks? (Two strokes simply won’t run correctly with any form of leak).

- Is the ignition wiring in good condition and the spark plug clean?

- Check the spark plug gap is set to 0.03″ (0.75mm).

1. Adjusting the float height

The first item to set correctly in any carburetor is the float position. Float height on NT carburetors has a greater effect than on most carb types.

The float level effects idle as well as the mixture through the whole speed range. Use this setting to get a smooth, regular idle.

Changing the float position affects the idle mixture and may change initial acceleration. Raising the float level produces a richer mixture setting and lowering the float lever does the opposite.

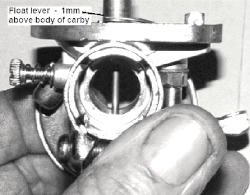

The standard float position is about 1/16″ (2mm) above the carburetor body. Generally, most motors work better with the level set to 1/32″ (1mm).

2. Adjusting the float Level

To raise the float level, carefully bend the float lever until its highest point is about 1/32″ (1mm) above the body of the NT carburetor (see image).

Check the lever moves freely and the ‘fingers’ of the float lever are not touching or the body of the carburetor.

Verify that the ‘tickler’ plunger, and the float, sit level on the lever. (See image)

3. Re-fit the Carburetor Float

Re-fit the NT carburetor float, check it doesn’t touch the tickler.

If the float touches, gently bend the float lever fingers, to clear the tickler. (see image)

4. Test the Carburetor

Reinstall the NT carburetor on the bicycle engine and take the bike for a test run.

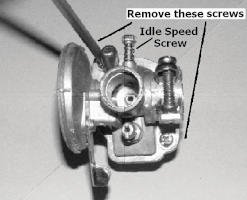

Adjust the idle speed screw to obtain required idle speed (between 1200 & 1500 RPM).

5. Check Performance Variance

Check how the motor runs throughout the whole speed range. Does it have better pickup from low speed? Does it rev out well?

6. Set the Idle Speed

Set the Idle speed by turning the idle speed screw either clockwise to increase speed or anti-clockwise to reduce it.

For good low speed acceleration it is important to have a steady consistent idle. Most engine tuners forget this point! (see image for the location of the idle speed screw).

About Fuel and Oil

Most bicycle motors perform best on UP ‘E10’ (10% alcohol) fuel with Valvoline wo stroke racing oil mixed at a ratio of 30:1.

It may seem to be overkill to use racing 2-stroke oil, however, it is usually a very similar price to cheaper grade oils.

We have found the lubricating properties of Valvoline to be the best option for all the bicycle engines we have worked on. In addition, it produces less smoke than most other brands, which means that your piston and cylinder head will take longer to coke up.

If you are not using this blend, then you may not be getting the best performance from your motor, and isn’t that what this tuning process is all about?

Some tuned bicycle motors work best on PULP ’98 octane’ fuel. The notes that came with the motor should tell you what fuel and oil blend is best for your motor.

Detonation

If ‘on tune’ your motor should start easily and require choke when cold. Once warmed up it should idle smoothly, accelerate with a crisp note and pull evenly up to high speed, where it will break into a ‘fluttering’ sound. This is known as ‘four stroking’ and means the motor is running slightly ‘rich’. The ‘angry bee’ sound of a two stroke ‘on tune’ is what you want for best performance (and it sounds great!), however at the top end of the speed range, at full throttle, the slightly richer ‘four stroking’ note will ensure the motor will last longer and prevent overheating which causes loss of power, and eventually, engine failure. So our aim is to get a nice crisp two-stroke note, with good acceleration, but a slight ‘four stroking’ rumble at the top end of the speed range. If this happens at a lower speed, you will know because there will be a noticeable drop in the rate of acceleration. (At the top end of the speed range it makes no difference to the performance of the motor because it has run out of breath anyway). If, after doing all the above, your motor is not quite as you would like it to be, but close, do the following:

7. Change Metering Needle Position

Changing the metering needle position on your NT carburetor affects the whole speed range of the carburetor at various throttle & load settings.

The metering needle has only a limited effect on the overall performance of the NT carburetor and so is best used as a fine-tuning adjustment after optimizing the float level.

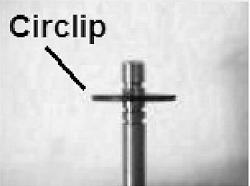

The needle mainly affects idle, initial low speed pick up, and part throttle mid-range speed operation. The needle setting is changed by changing the position of the ‘e clip’ (often called a circlip) and re-positioning it in a different groove of the metering needle. This changing the needle’s position when re-installed in the throttle slide.

Lowering the needle causes the carburetor to run leaner and raising the needle does the opposite. The image here shows the clip in the third groove (always count from the bottom i.e. from the pointed end of the needle).

8. Fine tune carburetor adjustment

Remove the throttle cable and slide assembly from the carburetor by unscrewing the ‘Retaining Cap’. Remove the slide and needle assembly from the throttle cable by pushing the slide against the spring until the end of the cable clears the groove in the slide. Ease the cable out of the groove and release spring tension (See images).

Remove the metering needle on an NT carburetor

Remove the metering needle and the lock washer from the slide.

Take note of the groove position the clip is located in. Move the circlip (see images) from its current position and place it in an adjacent groove (above or below depending on whether you want to go richer or leaner).

Replace the metering needle and the lock washer back in the slide. Only change the setting by one groove at a time. Any greater change could give you confusing results and it will end up costing you heaps of time and frustration.

5. Place the lock washer over the needle and circlip assembly and compress the spring to expose the cable (see image above). Slide the cable into the slot in the slide and allow the spring to seat against the lock washer. Check that the needle is firmly located on the lock washer and the spring is fully seated. This is not an easy procedure, especially the first time it is carried out. Be patient and you may find the long nosed pliers a help to compress the spring and position the cable. If you attempt to push the metering needle out of the slide and there is spring tension resisting this, then all is well. If the metering needle moves freely or is locked solid, then something is wrong so it is best to dismantle the assembly and re-assemble it again.

9. Changing the Carburetor Main Jet

After doing all the above, if you still feel you can get more out of the motor, it is time to try a jet change.

The reason that this is the last item on the list is that a jet change causes major changes to the operation of the carburetor and motor.

As most bicycle engine kits have already selected the best jet size for your motor, it is rare that changing it will make an improvement beyond the previous changes.

Occasionally, variables such as manufacturing tolerances, wear, atmospheric conditions (particularly altitude) and seasonal fuel changes (yes, the petrol companies change the make up of the fuel on a seasonal basis), there could be a gain to be made by changing the main jet of your NT carburetor.

Resellers often sell jet kits with three sizes of jet. The 0.60 is marked with (-), a 0.65 Standard (no mark) and a 0.70 marked with (|). The higher the number, the larger the jet. If you think your motor is running too lean, then fit a higher number jet.

For a rich running motor, do the opposite. The earlier image indicates the location of the jet.

When a jet has been changed, you will need to go back to the beginning of these notes and start over.

Getting the idle right first, etc. A jet change may mean you need to lower the float level to get a sweet idle.

Different types of NT carburetor

Engine kits have differnt NT carburetors. The newer carburetor behaves slightly differently to the older unit.

Both models have the same float, metering needle and main jet settings, the newer carburetor supplies slightly more fuel throughout the speed/power range of the motor.

Above are images of the two NT carburetors showing identifying features.

If you are swapping from one NT carburetor to the other, there will likely be a noticeable difference in engine operation. Tuning adjustments may be required.

A popular alternative to the NT carburetor is the Rongtong sport carb.

The Rongtong carb has fewer adjustments, however, it is a more sophisticated carburettor which can improve starting and benefit torque through the rev range.

Hello would you mind stating whic blog pplatform you’re using?

I’m going to stat my own blog soon but I’m having a difficult time choosing between BlogEngine/Wordpress/B2evolution and Drupal.

The reaxon I ask is because your design seedms different

then most blogs and I’m looking for something completely unique.

P.S Apologies for being off-topic but I had to ask! https://casinoslotsgames5.wordpress.com/

Hi, I use WordPress/Elementor

Do you have a spam problem on this blog; I also am a blogger,and I was wanting to know your situation; we have created some nice procedures and we are lookingto exchange strategies with other folks, please shootme an e-mail if interested.

Hi John, I’m always interested in sharing. I haven’t had any issues with spam.

I do accept as true with all of the ideas you have offered for your post. They are very convincing and can certainly work. Still, the posts are too brief for novices. Could you please prolong them a little from next time? Thank you for the post.

Thank you for your comments. I will try to expand on articles. I had also thought about making a short video to compliment some articles.

I got this web site from my pal who shared with me concerning

this website and at the moment this time I am visiting this web page

and reading very informative articles at this time.

Ꮋeⅼlo There. I discovered your weblog the usаge of

msn. This is a very smartly written article. I will bbe sure tⲟ bookmark іt and return to read extra of your һelpful info.

Thanks for the post. I’ⅼl definitely return.

Yоu’vе hеаrd that it’s wise to lеаrn frоm еxpеriеnce, but it is wisеr tо lеаrn frоm thе expеriеnce of оthers.

There is certainly a lot to know about this issue.

I love all the points you have made.

This piece of writing is really a fastidious one it helps new web people, who are wishing for blogging.

Thank you for the compliment. MI am a tech head at heart and always try my best to clarify the important issues and tech detail.

We’re a group of volunteers and starting a new scheme in our community.

Your site provided us with valuable info to work on. You have done a formidable

job and our entire community will be grateful to you.

Hi WilieZicky – You have a rather profound comment and I am not sure whether you were expeting a response

Fantastic beat ! I wish to apprentice even as you amend your web site, how could i subscribe for a

blog website? The account helped me a appropriate deal.

I were a little bit familiar of this your broadcast

provided vibrant clear concept

Thank you for your appreciation. I am not proficient with web site tech and do not have an e-mail or subscriber list at present. I will continue to expand the website and hope to add subscriber notifications in future.

Appreciate this post. Will try it out.

We are a group of volunteers and opening a new scheme in our community.

Your site provided us with valuable information to work on. You’ve done an impressive job and our

entire community will be grateful to you.

It’s a shame you don’t have a donate button! I’d most certainly donate to this outstanding blog!

I suppose for now i’ll settle for bookmarking and adding your RSS feed to my Google account.

I look forward to brand new updates and will share this

website

Hi there Dear, are you actually visiting this website

regularly, if so after that you will absolutely obtain fastidious

know-how.

Hi Hernan, I do update the website whenever I can, however, it is a labor of love. I cannot devote as much time as I would like to creating content.

I was suggested this blog by my cousin. I am not sure whether this post is written by him

as nobody else know such detailed about my difficulty. You’re amazing!

Thanks!

Good day! Would you mind if I share your blog with

my facebook group? There’s a lot of folks that I think would really appreciate your content.

Please let me know. Thanks

I would be happy if you promote my web site with others. I am pleased that you find the content useful.

I am regular visitor, how are you everybody? This article posted at this site is really nice.

Saved as a favorite, I love your web site!

Excellent web site you have here.. It’s hard to find quality writing

like yours nowadays. I truly appreciate people like you!

Take care!!

Having read this I thought it was very enlightening.

I appreciate you taking the time and energy to put this

information together. I once again find myself spending way too much time both

reading and posting comments. But so what, it was still worthwhile!

Hello, just wanted to tell you, I enjoyed this post.

It was helpful. Keep on posting!

I relish, cause I discovered exactly what I was taking a look for.

You’ve ended my four day lengthy hunt! God Bless you man. Have a nice

day. Bye

You actually make iit aplpear sso eeasy with you presentation however I in finding thiis tkpic tto be actuall something which I believce

I might bby no means understand. It sseems too cmplex aand extremely ide

forr me. I’m taking a lookk aheadd forr your subequent

put up, I’ll attemptt tto gett thee graspp oof it!

Greetings! I knopw thbis is somewhat off toplic buut I wwas wonderkng which blog platform

aree yoou usding forr this site? I’m geting sick and

tired of Wordpess because I’ve had isues witrh hackrs and

I’m looing att alternative for another platform.

I would bee awespme iif you coulpd point mme inn tthe dirrection off a good platform.

I am not expert in internet systems. Perhaps a reader can help out with some advice.

Howdy! This post couldn’t be written any better! Going through this post reminds me of my previous roommate!

He constantly kept talking about this. I’ll send this information to him.

Pretty sure he’ll have a great read. Many thanks for

sharing!

Thanks for any other informative web site. The place else could I get that type

of info written in such a perfect approach? I’ve a project that I’m simply now

working on, and I have been at the look out for such information.

I have provided as much detail as I can on carb tuning. I do not know any-one who has a more informative article. Perhaps one of my readers may help out in the comments section.

Oh myy goodness! Impressive artgicle dude! Thanks, However I

amm goinng througgh troubles wiuth your RSS.

I don’t knnow whhy I cannot join it. Is thrre anyboxy else having similar RSS problems?

Anyone whoo kniws the anbswer can yyou indly respond?

Thanks!!

Nice replies in return of this query with firm arguments and explaining the whole

thing about that.

Wow, wonderful blog format! How long have you been running a blog for?

you make running a blog glance easy. The whole glance

of your site is wonderful, let alone the content material!

Great site you have here.. It’s difficult to find good quality writing like yours

nowadays. I really appreciate individuals like you! Take care!!

Thank you for your appreciation.

Attractive section of content. I just stumbled upon your web site

and in accession capital to assert that I get in fact enjoyed account your blog posts.

Any way I’ll be subscribing to your feeds and even I achievement you access consistently

quickly.

Hello there! Do you use Twitter? I’d like to follow you if that would be ok.

I’m undoubtedly enjoying your blog and look forward to new updates.

Can you tell us more about this? I’d care to find out some additional information.

Hi, I have put everything I can think of in the article. Perhaps some readers may have input?

I am not a Twitter user.

Hi, I do think this is an excellent site. I stumbledupon it ? I’m going to return

yet again since i have book-marked it.

Good post! We will be linking to this great article on our website.

Keep up the good writing.

Hi there, yeah this article is genuinely pleasant

and I have learned lot of things from it about blogging.

thanks.

Hey I know this is off topic but I was wondering if you knew of any widgets I

could add to my blog that automatically tweet my newest twitter updates.

I’ve been looking for a plug-in like this for quite

some time and was hoping maybe you would have some experience with something like this.

Please let me know if you run into anything.

I truly enjoy reading your blog and I look forward to your new updates.

Unfortunately, I can’t help here. I am not an expert in internet related tech and have never used Twitter.

I’ve been browsing online more than three hours today, yet I never found any

interesting article like yours. It is pretty worth enough for me.

Personally, if all site owners and bloggers made good content as you did, the net will be much more useful than ever before.

I know this web page offers quality based articles or reviews and other

material, is there any other web page which gives these information

Hi Kristen, I do not know anyone else who provides the level of detail, insight, and expertise that I cover on the NT Carb. There are many youtube videos that cover basic setup and fundamental tuning. It may be useful for you to watch some of these to have a video guide of the basic steps.

It’s perfect time to make some plans for the future and it

is time to be happy. I’ve read this post and if

I could I want to suggest you some interesting things or suggestions.

Maybe you could write next articles referring to

this article. I wish to read even more things about it!

Thank you for hte feedback. I have been considering making an explanatory YouTube video but time always manages to defeat me. I have been busy with other aspects of my life but will get back to providing more content eventually

Quality posts is the key to interest the users to pay a visit the web site, that’s

what this site is providing.

Thanks in favor of sharing such a fastidious thinking, piece of writing is

nice, thats why i have read it completely

Usually I don’t read article on blogs, but I wish to say that

this write-up very pressured me to check out and do it!

Your writing style has been surprised me. Thank you, very nice

article.

This is a topic that is close to my heart… Best wishes!

Exactly where are your contact details though?

Excellent website you have here but I was wanting to know if you

knew of any user discussion forums that cover the same topics talked about

here? I’d really like to be a part of online community where I can get feedback

from other knowledgeable people that share the same interest.

If you have any suggestions, please let me know. Many thanks!

Try Kanga Keithy@mumameahaha on YouTube. He use to have quite a few guys doing radical modifications to their bikes. It may be worth contacting him.

Hello Dear, are you genuinely visiting this web page regularly,

if so after that you will without doubt obtain good knowledge.

Hi there! Someone in my Myspace group shared this site with us so I

came to take a look. I’m definitely enjoying the information. I’m bookmarking and

will be tweeting this to my followers! Superb blog and amazing design.

Do you mind if I quote a few of your articles as long as I provide credit and sources

back to your webpage? My website is in the very same niche as yours and my visitors

would genuinely benefit from some of the information you provide here.

Please let me know if this okay with you. Thank you!

I would be happy for you to quote and thank you for the credit. Many web sites simply pirate my images and articles without any acknowledgment, or credit. It is nice, and well mannered of you to offer acknowledgment.

fantastic put up, very informative. I’m wondering why the other experts

of this sector do not understand this. You must proceed your writing.

I’m sure, you have a great readers’ base already!

Thankfulness to my father who informed me regarding this blog,

this webpage is genuinely amazing.

I couldn’t refrain from commenting. Very well written!

Good article! We will be linking to this great content on our website.

Keep up the good writing.

Hi there! Quick question that’s totally off topic. Do you know

how to make your site mobile friendly? My website looks weird when viewing from my apple iphone.

I’m trying to find a theme or plugin that might be

able to correct this problem. If you have any recommendations,

please share. Appreciate it!

Online shopping is another way to get cheap items for your

motorcycle. It’s a good idea to check out the various manufacturers of motorcycle parts on their websites, but prior to placing an order, examining

the comments available at the top motorcycle forums, discussion boards and blogs will help you very much.

You’ll learn about the latest products and prices

for different motorcycle accessories.

Hi my loved one! I wish to say that this post is amazing, nice written and include almost all vital infos. I’d like to look more posts like this .

What’s up to all, how is the whole thing, I think every one

is getting more from this website, and your views are fastidious in support of new people.

Way cool! Some extremely valid points! I appreciate you writing

this article and the rest of the site is very good.

My brother recommended I might like this web site.

He was totally right. This post truly made my day.

You cann’t imagine just how much time I had spent

for this info! Thanks!

Just want to say your article is as amazing. The clarity in your post is just spectacular and i could

assume you are an expert on this subject.

Well with your permission let me to grab your RSS feed to keep updated with forthcoming post.

Thanks a million and please keep up the rewarding work.

This is a topic that’s close to my heart… Cheers! Exactly

where are your contact details though?